Warehouses are fast-paced environments where many pressure points in supply chains converge. When these pressure points are factored into space design and management, the capacity to gain and retain a competitive edge is there for the taking. This special management increasingly involves high-performance networking to underpin an increasingly automated warehouse with Wi-Fi-first devices – from sensors to driverless tech.

So what are the most common ‘pain points’ we see when it comes to warehouse Wi-Fi? There’s a long list, including slow picking and inaccurate data, but one thing they all have in common is their net result: an inefficient warehouse.

Warehouses are difficult environments for high-performance networking, and the odds are stacked (or racked!) against you. But so many of these pain points are caused by avoidable mistakes.

Below we delve into the problems warehouse managers and their IT teams report the most often, exposing their knock-on effect as well as the causes.

1. Inefficient picking

- Slow WiFi can cause delays in retrieving picking information from the central inventory management system, leading to longer wait times for pickers and slower overall picking rates

- Frequent disconnections force pickers (human or robotics!) to wait for devices to reconnect and/or reboot, costing additional time

- Pick paths become defined by the lack of wireless coverage rather than being defined by efficiency

2. Inaccurate inventory tracking due to packet loss

- Stutters or breaks in connectivity can result in a loss of data packets travelling between scanning devices and WMS, causing discrepancies between inventory and its records

- Lag in data updates due to slow speeds can cause staff to double pick

- Manual reconciliation is then necessary to avoid higher shrinkage rates

3. No real-time communications between staff on order updates, schedules, safety alerts, etc.

- Not only can a lack of real-time comms impact the efficiency of the warehouse, it can also put employees at risk if safety alerts are not swiftly shared, risking compliance issues

4. Equipment downtime, especially Wi-Fi-first devices (which are increasing)

- Wi-Fi-first devices are rapidly becoming the backbone of warehouses, especially ‘smart’ ones. Voice picking, IoT, robotics and wearable tech are all becoming essential tools for driving down inefficiencies – but they all rely on seamless, uninterrupted, superior connectivity

- Often, businesses adopting newer tech think that these systems aren’t providing good ROI, when in reality they simply need the quality of connectivity needed to

5. Errors in quality control

6. Risk of data breaches through unauthorised access, malware attacks, and more during downtime or at weak points in the network architecture

- Older networks may no longer receive firmware updates or security patches, leaving your WMS data potentially open for taking

- Older networks typically have weaker encryption protocols (such as WPA which is no longer guaranteed to be secure)

- Responding to security risks is much harder to do in a timely manner with older networks that are not bolstered by machine learning, automated processes and real-time analysis

- Poor role-based security that cannot safeguard your network in a workplace where multiple devices can be assigned to a single user

These issues all ultimately converge to cause delayed dispatching, revenue loss through data inaccuracies, higher shrinkage rates, and customer dissatisfaction.

Longer-term, slow, unscalable or patchy networks cause adopted technologies reliant on high-performance connectivity to ‘fail’. This has a huge knock-on effect on the ROI of investments like sensors, driverless tech, and expensive warehouse management systems.

So what causes these issues?

1. Lack of scalable bandwidth

As warehouse technology rises, bandwidth is a huge factor that businesses must consider – it underpins productivity in a digital age, and waiting until problems arise means you’re already feeling the financial impact

2. Channel congestion

This is largely a removed issue for warehouses who have shifted to Wi-Fi 6, but for many this is becoming a challenge for IT functions, reducing speed and capacity, as well as causing bottlenecks – hardly ideal for WMS

3. APs not designed for challenging environments

Warehouses are tough environments where your tech needs to be even tougher. Outdoor connectivity for loading bays, dust, cold, heat… all these factors should inform choices during network design

4. APs with limited throughput capacity

Again, individually small components of your network can determine overall network performance, and older access points are often unable to deliver the throughput needed for today’s warehouses and their connected devices – edge to core

5. Black spots in coverage

Poor network design resulting in gaps in coverage that wreak havoc on picking. We’ve seen cases where racking areas can’t be used due to the inability to pick stock in those zones

6. Interference from electronics, metals, racking, building structures

This is a huge issue in warehousing, with so many objects and materials – static and moving – that can interrupt a consistent signal. This is especially common where networks were planned during construction, or off-plan.

7. Wrong AP antennae

Warehouses are unique environments and the traditional ‘donut’ signal won’t provide the coverage you need. Specialist access points are required with these spaces in mind

8. Wrong AP placement

Poorly placed APs can lead so many warehouses to do entirely the wrong thing – add more! Just take a look at our article on ‘quick warehouse Wi-Fi fixes that don’t work’!

7. Poor configuration

Managing wireless networks throughout supply chains requires a seamless configuration, since supply chains are themselves aiming on seamlessness. Poorly matched security protocols, channel settings, mismatched power levels, and many other mistakes are easy ways to ensure your supply chain has too many sticky patches to be efficient.

It’s no secret – warehouses are more challenging than other environments when it comes to designing, installing and maintaining high performance connectivity, but we see a wealth of industry experience around us that is helping transform these spaces just by gaining a stronger understanding of how they flow.

What are your pain points when it comes to connectivity in your warehouse?

With the increasing reliance of warehouses on technology, it is no surprise that as IT advances, the opportunity to close gaps in efficiency and reduce the impact of errors is one that the most successful warehouses are taking advantage of. High performance networking – and in particular wireless networking – underpins much of this emerging technology. Below we examine why superior Wi-Fi in warehouses is vital if businesses are to gain a competitive edge with today’s evolving supply chain.

Faster connectivity:

Next-gen networking technologies provide faster and more reliable connectivity within the warehouse environment. This enables real-time communication and data exchange between various systems, such as inventory management, warehouse management, and order fulfilment systems. With improved connectivity, warehouse operations can be streamlined, eliminating connectivity issues and enabling uninterrupted operations, improving efficiency.

Improved mobility:

It’s not all about speed. Next-gen networking technologies, such as Wi-Fi 6, offer improved coverage, enabling wireless connectivity throughout the warehouse. This is particularly important for the rising number of mobile devices used by warehouse staff, such as handheld scanners, tablets, and wearable devices, to say nothing of emerging tech yet to become widely adopted. With reliable wireless connectivity, employees can access real-time information, update inventory records, and communicate with colleagues from anywhere within the warehouse, improving productivity, responsiveness and the accuracy of inventory management and tracking.

Supporting successful warehouse automation:

Linked to both speed and coverage, superior Wi-Fi is crucial for supporting warehouse automation initiatives which are seeing rapid adoption due to their ability to deliver and maintain a competitive edge to businesses. Automated systems, such as robotic picking systems or autonomous guided vehicles (AGVs), rely on Wi-Fi connectivity to communicate with the warehouse management system (WMS) and coordinate tasks efficiently. A reliable and high-speed Wi-Fi network with 100% coverage delivers ROI on the cost of having implemented automated processes and devices.

Supporting IoT integration for greater awareness:

Similarly to larger automated machines and tools, warehouses are increasingly adopting smaller IoT devices such as sensors to automate processes, track inventory, and monitor equipment. Next-gen networking infrastructure supports the seamless integration of these IoT devices, allowing them to communicate and share data efficiently. This integration enables real-time monitoring, predictive maintenance, and optimization of warehouse operations, leading to reduced downtime and cost savings on building and contents maintenance. Find out more about designing wireless networks with IoT in mind.

Cloud integration and data management:

Next-gen networking facilitates seamless integration with rapidly expanding cloud-based services and platforms which we are already seeing become a pillar of networks. This easy integration enables warehouses to leverage cloud computing power and storage for data-intensive applications, such as data analytics, machine learning, and artificial intelligence. By leveraging cloud services, warehouses can optimise their data management processes, gain actionable insights, and make data-driven decisions to improve operational efficiency and inventory management – all without needing additional data storage.

Security and data protection:

Next-gen networking technologies incorporate advanced security features, including robust encryption, authentication mechanisms, and network segmentation. In a warehouse setting, where sensitive data such as inventory information and customer details are stored and transmitted, ensuring the security and protection of data is of paramount importance. This is only becoming more critical as the number of devices (including those that are cloud-first) grows, permitting more breach points for cyber-attacks. Next-gen networking provides the foundation for implementing strong security measures to safeguard critical information from unauthorised access and potential cyber threats.

Voice and video communication:

In some warehouse operations, voice communication is critical for coordinating tasks, providing instructions, or addressing safety concerns. With superior Wi-Fi, voice-over-Wi-Fi (VoWi-Fi) solutions can be implemented, enabling employees to use wireless headsets for real-time voice communication. Additionally, Wi-Fi can support video communication for remote collaboration, troubleshooting, or training purposes, improving communication effectiveness and reducing the need for physical presence.

Future-readiness:

As technology continues to advance, warehouse businesses need to be prepared for future requirements. Superior Wi-Fi provides the foundation for adopting emerging technologies, such as augmented reality (AR) or virtual reality (VR) for warehouse training, or advanced analytics for operational optimisation. By investing in a robust Wi-Fi infrastructure, warehouse businesses can adapt to evolving technology trends and remain competitive in a rapidly changing industry.

Wondering whether your wireless network can support your warehouse into the future? Find out about our range of WiFi surveys here.

Rising customer expectations, an ‘on-demand’ supply chain, the complexity of global logistics, the move towards customisation – these and many other challenges are forcing players in manufacturing and supply chains to transform their operations in order to retain a competitive edge.

Both unearthing and implementing these transformational changes – however – requires a huge amount of digging into productivity, efficiency, and where gaps can be closed through innovation. To add to the size and scope of this task, as technology advances, the rate at which these gaps become evident increases; businesses slow to identify them are left further behind, faster.

Tackling these major challenges demands a shift in the way efficiency and productivity are handled, namely moving away from human monitoring, analysis and review towards automated systems that take advantage of machine learning, AI and cloud-based management.

Enter IoT and its capacity to help find productivity gaps and close them more accurately, efficiently, and affordably than humans ever can. The data generated by these devices provides organisations with real-time, data-driven insights that can have automated corrective actions, and embed an agile approach to change and transformation within the business.

McKinsey research estimates that by 2025, IoT devices and their application could save businesses over £350 billion per year in operational costs.

Benefits of Adopting IoT & Automated Monitoring of Efficiency

Reducing operational costs

Optimising how products are made, moved and managed throughout your supply chain carries huge cost savings through:

- Better machine management, improving output, reducing downtime and extending machine lifetime. Deloitte research identified that predictive maintenance solutions are expected to reduce the costs of maintaining machines by 40%

- Reducing energy usage of your spaces. When combined with the power saving functionality of WiFi-6, the capacity to reduce the cost of energy is considerable

- Better use of devices and tools through tracking every single one via WiFi and RF. Track usage and location to within metres so the right items can be found, and ensure you’re only buying essential hardware

- Automate certain processes, reducing the size of your workforce and the associated costs of payroll and human error

Health & safety

Your workforce is one of – if not the most – expensive cost to your business. IoT can help increase its profitability through:

- Monitoring the safety of employees in high-risk environments (such as warehouses) to avoid accidents, damage and associated costs

- Tracking the health of your teams to ensure productivity and avoid entire teams needing sick leave within short windows of time

Improved Production

Improving how each element of your production line performs means faster production times and better output as a whole, primarily through:

- IoT and industry management solutions are driving end-to-end supply chain visibility, with around 80% of interactions happening across cloud-based networks. Simply put, if you can see your whole supply chain you have an advantage over those without visibility

- Optimising management of inventory and stock flow to avoid bottlenecks in materials or goods all the way through the supply chain, from the production line to the end-user

- Better machine output. Harley-Davidson famously improved efficiency in their Pennsylvania warehouse to the extent that building a motorbike went from taking 21 days down to 6 hours

- Production can handle more complex processes, such as mass customisation which is becoming a major decision-making factor for consumers. The production of 20 SKU X items can be followed by 10 SKU Y items with ease since IoT can both save time on routine operations, and also provide insight on the greater number of tools and materials required

Realising the Potential of IoT in Warehouses & Avoiding Failed Adoptions

The benefits of IoT are clear, however successful deployments are based on more than just a plug and play approach, and many organisations who fail to adequately plan see their investment fall flat.

So what are the main reasons IoT adoption in warehouse environments fails? An initial factor that can lead to failure is a human one. A business culture that is not ready for a data-driven approach to strategy can cause serious issues, from resistance to the change to not having the adequate skillset available, either in house or external. This can be a challenge to overcome post-deployment.

The simplest and most easily remedied reasons for failure, however, are IT ones, including:

- Security breaches due to an expanded network with multiplied breach points. Network security must be at the forefront of IT strategy, including identity authentication, encryption and physical security.

- Cumbersome IT infrastructures that don’t allow for easy data integration between new IoT solutions and existing technology, mainly how data is ported between networks and formats. Trying to fit IoT technology into legacy hardware is often done to try and keep project spend down, but in reality is error-prone and costly in the long run.

- IIoT is best leveraged when supported through wireless connectivity – connecting everything via ethernet would be cumbersome, inagile and expensive. But legacy networks or networks designed without IIoT in mind end up causing your adoption to fail due to patchy coverage for devices, slow speeds and the inability to scale or flex to adopt additional tech.

There’s no doubt that adopting a data-driven business strategy with IoT at the centre puts pressure on your IT infrastructure, from a rising number of inter-connected devices on the edge, all independently aggregating and analysing data, to consistently higher traffic, blurred network edges and higher security risks.

Networks that cannot provide the necessary connectivity foundations for IoT will prevent your organisation from realising the value of IoT – both it’s current and exponentially bigger future potential.

This is where next-gen networks, primarily Wi-Fi 6 and cloud-based networks excel. Wi-Fi 6 delivers 160 MHz of bandwidth, data rates of 10Gbps, and operates at 5 GHz, giving superior performance that’s quite literally made for IoT, with faster throughput, reliable and robust connectivity, significantly less congestion and reduced power consumption. Moving to a cloud-based network removes limits on your IT infrastructure, making it truly scalable, offering easy deployment with zero-touch-provisioning, and giving total control of every device from anywhere, any time. Cloud-based networks are ideal for multi-site businesses where having locally managed networks are becoming increasingly complex and disjointed – for example supply chains, manufacturing and logistics. In short, cloud-based networks mean you can build, monitor, manage and scale your smart spaces faster, easier, and with better outcomes.

Any network which looks to take advantage of constantly evolving tech such as IoT needs to be designed with the future in mind – both the future of your business and the future tech it will look to adopt. If you’d like to find out more about next-gen networks to support IoT, get in touch with us. Our network engineers are experts in wired and wireless networks in warehouses, and have the latest CWISA accreditation in IoT solutions and administration.

Warehouses are complex environments for WiFi. Users and devices are constantly moving from place to place, the signal is attenuated by racking, and there is a large area to cover. As a result, many systems that would perhaps work well in a simpler environment (such as an office) are not transferable to the warehouse.

When issues inevitably arise, it is understandably often a kneejerk reaction to make quick changes to try and mitigate the problems caused by a struggling network. These include:

Add more access points

This may well be the solution to your problem. Still, it needs to be managed carefully to ensure we’re covering the desired areas without causing interference to the rest of the network.

Install warehouse WiFi extenders

This technology has many names (warehouse WiFi boosters, repeaters), but all do the same thing – extend your Wi-Fi coverage; however, it causes additional jitter, latency, delay, reduces overall throughput and increases interference. These types of solutions should be avoided. Trust us, there are better options.

Meshing

Meshing can be used to solve coverage and can work well under certain stances. However, when you try to mesh multiple APs, place those APs too far away from each other or connect numerous devices, you can quickly run into issues. Meshing can work well in homes or small offices but it doesn’t support the capacity or throughput needed by most warehouses.

Turn up the power

Increasing the transmit power of your access points may seem like an easy way to improve coverage. However, Wi-Fi is a two-way conversation, and your devices also need to talk louder to send that signal back. In most battery-powered devices, this is not an option.

Use wider channel widths

Using wider channels enables higher data rates, making it appealing for many users. However, there is a limited amount of spectrum to use, and as a result, wider channels can often cause interference.

Usually, these ‘solutions’ are akin to placing a plaster on an open-heart wound, and in some cases, may create more problems than they solve! You’re then left with a more convoluted IT infrastructure that’s harder to monitor, harder to manage, and with more things to break down or go wrong. In short, you’ve compromised the integrity of your network so that it is unlikely to offer even, reliable performance in all areas you need it to.

At Redway Networks, we take a different approach to designing networks. Every warehouse is different, and as a result, we tailor each design to our customer’s needs. We consider the layout of the building, the materials inside, what devices are in use, how many and what future plans the business has for Wi-Fi usage. To deliver a successful design that will last for years, we utilise industry-leading tools such as Ekahau, giving us the ability to plan signal strength, data rates and mitigate interference. Once a network is in place, we always conduct a verification survey to verify our design and optimise performance. This gives us the ability to get your network working from day one.

With extensive experience in the logistics and manufacturing sector, we understand the challenges warehouse environments face when it comes to connectivity. We also know how to future-proof your business for the future of supply chains through networks that can adopt emerging tech such as machine learning, automation, real-time analytics and hyper-agile connectivity.

If you’d like to talk to us about your wireless network, get in touch with our Warehouse WiFi engineers today.

We all know that designing WiFi for warehouses is more specialist than the average office building. One of the key points to getting a fast, reliable wireless network in your warehouse is the initial design, but equally important are the wireless products.

There are many interfering factors in the warehouse which can result in a solution offering poorer performance than elsewhere. Warehouse layout, racking arrangement, environment (hot or cold) stock type and how often that stock is moved all affect the performance of the WiFI. In addition, you have the building type ( most warehouses are made from metal which isn’t ideal for radio frequency) plus high ceilings, ceiling angles, and interfering materials all add to the complexity.

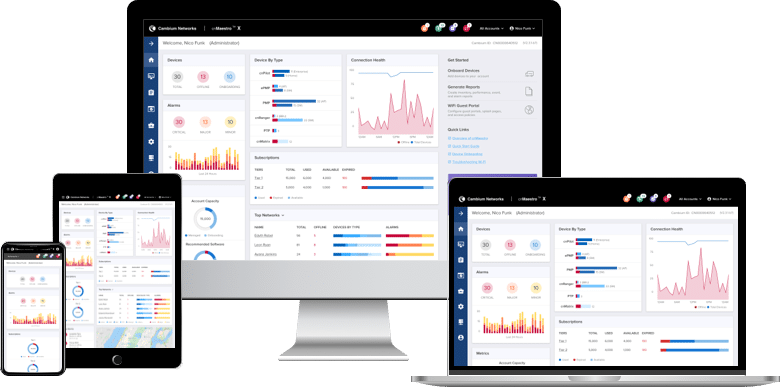

For this reason, when proposing a wireless infrastructure for the warehouse we recommend Cambium Networks as it has many antenna options so we can tailor each solution we offer. Cambium’s access points are IP67 rated and with a minimum 3-year warranty are built to last. On top of all that Cambium’s entire solution is cloud-managed enabling faster deployment, configuration and troubleshooting for the lifetime of the network.

Our top reasons for evaluating Cambium when looking for a new wireless solution are:

- Easy Backhaul for connecting all your buildings onto one network without trenching or running cables

- Tried and proven e500, e501, e502 and now e700 high-temperature access points for those hot high ceilings

- Easy to power up and cable the access point with any CCTV security cameras, just plug and play

- One single pane of glass for all your monitoring and control functions for clients, switches, access points and cameras

- Full built-in alert functions to help you control

- Full mesh capable of your failover needs

- Up to lifetime warranty, three-year standard

- Built-in mounting and grounding kits

- No need for additional antennae, they are built-in, even sectional

- Now with the new e700 you can go to very high-density solutions

- A Cambium solution is much cheaper than other brands

- No ongoing license costs

- Use with your local controller, local cloud, or with full cloud deployment

- Deploy with cable and electricity or no cable, it is up to you

- Now you can deploy up to 150 Meter Radius solutions

If you’d like to know more about Cambium for your warehouse, contact one of our warehouse wireless experts today.

Our WiFi expert Leigh Hayes talks to Warehouse and Logistics Magazine (WLM) about the complexities of designing a warehouse Wi-Fi network that supports resilient and efficient supply chains.

What type of products and services does your company offer to warehousing and logistics?

Redway Networks is a specialist in wireless networks for warehouses that underpin efficient, accurate and resilient supply chains.

One of our core strengths when it comes to servicing the logistics sector is our expertise in designing wireless networks that support the specifics of warehouse environments. From the start of a project, our primary focus is delivering a strong design based on accurate data, sector experience and extensive product knowledge; it’s the most essential part of what we do.

Explain the difference to installing Wi-Fi within a warehouse than in say an office environment?

It’s vital with any Wi-Fi installation to understand the space you’re working in, but in warehouses, this is even more critical. Many interfering factors specific to this environment can result in a solution offering poorer performance than elsewhere. Warehouse layout, racking layout, stock type and how often that stock is moved can all affect your wireless, in addition to the type of building (most warehouses are made from metal which isn’t ideal for RF), ceiling angles, and interfering materials.

Office environments are more straightforward in terms of design as the ceilings are lower and there are fewer obstructions and interfering materials. It sounds complex, but really, it’s simple; once you can understand and anticipate the unique needs of the warehouse environment, you have a good foundation for a successful project.

Tell us about the challenges warehouses typically come up against and how do you help address them?

Warehouses are complex and challenging environments, so the most common problem we see is poor performance brought about by a poor design. This is often caused by a lack of understanding of how Wi-Fi will perform in warehouse environments post-installation.

If we are approached by a client that is experiencing Wi-Fi issues, we have a list of qualification questions to try and establish what might be causing the issues. We usually recommend progressing to a troubleshooting or fault-finding warehouse Wi-Fi survey where one of our certified engineers will attend the site to gather data and pinpoint the problem. Once the data has been crunched by our engineers, we invite clients on a call to explain the identified issues and discuss remedial actions for the short and longer term.

What differentiates Redway as an independent vendor and how do you help businesses choose the right technology?

Our experience in the logistics sector is vast, and as a result we know that one size rarely fits all when it comes to wireless networking in warehouses. We take the time to understand the unique requirements of a business in terms of its processes, people, and devices, as well as its needs and strategies for future growth. Being an independent vendor allows us to recommend solutions that put our clients’ business at the centre, with no product partiality.

In which sectors do your warehouse customers typically operate in and what size of business do you work with?

Our clients span the supply chain, from manufacturing to distribution, as well as a range of sectors including food, engineering, retail and many more. Our clients are also cross-vertical, so our solutions range from single warehouse installations to multi-site channels handling distribution across the UK and Europe. We’re also experienced in working on greenfield sites where flexibility and an understanding of construction projects is key.

Highlight what’s unique about the solutions Redway offers?

I would say it’s our sector knowledge and focus on customer engagement that make our solutions stand out. We have a highly technical sales team which means that from the first conversation our clients can feel confident in our ability to understand their requirements and advise on the next steps. We focus on consulting them at every stage to make sure their input helps drive the project forward.

We also understand that a solution is only a real success when it responds to our clients’ needs; not when we complete the installation. Our engineers offer extensive post-installation support that guarantees the performance their business needs beyond project completion.

What tips would you give a business looking to improve its warehouse automation?

1. Invest in design. It’s crucial for ensuring a successful project.

2. No, really, invest in design! Our heavy focus on design is fuelled by our ‘right first time’ approach which avoids the costly exercise of correcting cut corners later.

3. Don’t go for the cheapest option; it’s cheap for a reason. Your wireless technology underpins the growth of your business, so invest in the correct infrastructure.

4. Use access points that are designed specifically for warehouse environments. This gives you control of the RF and ensures your investment will last for years to come.

5. After your new network is installed, do not assume everything is fine; validate your wireless performance and make adjustments where necessary to hardware and software.

Did the Covid-19 outbreak affect your business?

Yes and no. The initial lockdown caused delays to some of our projects as we were unable to go on-site, but as soon as businesses had to adapt to new ways of working it became evident to most that investing in wireless networking was vital for business continuity. High-performance WiFi is now a major facilitator of social distancing in the warehouse, which helps keep operations both efficient and safe.

What has been the biggest news for Redway in 2020?

2020 has been an incredible year for Redway. We’ve continued to grow as a business despite COVID 19, both in terms of our clients and our team, which continually grows in size and in skills. We’ve also been expanding our product knowledge, working closely with more manufacturers to ensure we keep offering the best and latest technology the market has to offer.

Can you provide any recent examples where you have improved the connectivity of a warehouse?

We recently worked with a client that was losing tens of thousands of pounds a day as their staff couldn’t pick orders reliably or efficiently. With our troubleshooting wireless survey and prompt remedial actions, we created a short-term fix to see them through a busy period. Once this had passed, the client invested in a complete overhaul of their WLAN and infrastructure to push productivity forward and future-proof operations. This resulted in call from the MD thank us for the work we did.

What are you looking forward to as a business in 2021?

2021 is certainly going to be a very interesting year for logistics and there is a lot to look forward to. The technological advances have led to an increase not only in the integration of warehouse devices such as scanners, laptops and wearables, but also the rise of Big Data and IoT. For me, the biggest change will be the new Wi-Fi 6 standard; it will be seen in more and more devices and redefine what is possible.

2021 will certainly have its challenges too. Problems with coverage, capacity and reliability are highly common, and with tough times facing logistics in the months and years ahead, many of these issues could make or break businesses.

How using pre-deployment software such as Ekahau can help industrial and manufacturing warehouses plan for better WiFi performance.

Designing and implementing a WiFi network the right way will minimise problems and future proof your warehouse operations. Get the design wrong, and it will be a major headache for everyone.

For industrial and manufacturing warehouses, high performing WiFi is critical to the supply chain. But it is also complex as there are many types of obstructions in a warehouse that you don’t get in in traditional office spaces such as high ceilings, obstructions, changing environments or extreme temperatures. And your WiFi must be able to deal with all of these.

Poor warehouse WiFi can literally bring down your manufacturing line. For example, logistics teams use handheld devices to track inventory and without WiFi access, those handhelds cannot report inventory usage or arrival – leaving your company with too much or not enough inventory. Something which directly impacts operational costs, customer service and the bottom line.

Design is vital for successful Warehouse WiFi project

No two warehouses are the same and you need to be careful in setting up and maintaining your WiFi. There are lots of issues in a warehouse you need to consider such as large numbers of access points, mezzanine levels, unpredictable racking of products, moving forklifts, very high ceilings and safety constraints.

When you deploy a wireless network without pre-planning you will run into trouble. High-performance WiFi needs to be planned and evaluated before you deploy. Even before you order or install your equipment you should perform a pre-deployment site survey to measure the radio signal propagation on the manufacturing floor. This will help you plan the appropriate number of access points and their locations and discover any neighbouring interferences that could impact your warehouse WiFi performance.

Warehouse WiFi that provides superior roaming

In the manufacturing environment, forget about the tablets, forget about the phones, in the warehouse you will encounter a variety of handheld devices, some good and some bad in terms of signal strength and rate jumping. When you are planning your WiFi network during site surveys, keep in mind the types of devices and clients used in the plant. Wireless is about mobility. Old networks were not designed for roaming because coverage was not continuous. Even new networks are sometimes not correctly designed for roaming. A mix of standalone and controller driven access points will rarely be configured for roaming between them, if even possible. And warehouses encounter WiFi problems with roaming more than anything else, so keep this in mind.

WiFI challenges in the modern warehouse can sometimes be as large as the warehouse itself. Whether its high ceilings, obstructions, changing environments, extreme temperatures or dusty environments – delivering a seamless WiFi experience to small devices within the warehouse is a challenge.

At Redway Networks, our experience in warehouse WiFi has helped us understand some of the root problems surrounding under-performing and unreliable warehouse networks. We’ve come across many small to medium sized businesses that are experiencing issues with their wireless network and are not sure where to start.

A reliable wireless infrastructure streamlines operations within the warehouse by reducing those inefficiencies and errors associated with constant disconnections of handhelds, mobile computers, printers and tablets. The benefits of good warehouse WiFi are endless and include: improved staff efficiency, less manufacturing delays, more orders picked and fulfilled and the ability to implement new technologies – which in turn meets today’s on-demand supply chain and improves customer service. Businesses who have implemented an enterprise grade wireless infrastructure have positioned themselves with a competitive advantage over those who have not.

Some of the most common mistakes we’ve seen in WiFi for warehousese are the overuse of omni-directional access points, incorrect access point placements (such as mounting APs on high ceilings or mounting ceiling APs vertically) and the use of ‘indoor’ APs that are not IP rated. This means the coverage changes when you walk around the warehouse and you experience drop offs for the end user, which in turns slows down the handover. For a seamless experience, there are so many elements to take into consideration when choosing the right warehouse WiFi solution and its vital to get the foundations right from the start to avoid any pitfalls.

Often, the main cause of poorly implemented warehouse WiFi is related to a lack of knowledge and planning. Using the right wireless technology is a critical component if you expect a successful implementation but implementing best design practices such as using directional antennas, reducing CCi with careful channel planning and ruggedised access points are sometimes overlooked.

The warehouse wireless network is far more complex than the one in your office, which is why it requires an enterprise grade AP that offers interference mitigation and a stronger signal. A properly designed wireless infrastructure will not only improve efficiency but future proof your business and prepare it for supporting more mobility such as the internet of things (IoT).

We are here to help businesses of any size improve warehouse efficiency through high-performance cloud-networking. So if you’d like any help or advice, contact us today.

Whether you have a single or multi-site supply chain, there’s no denying that warehouses are a hive of activity, and a hub for manufacturing and logistics – and they’re getting busier and busier.

Hardware and software in the warehouse are both on a steep incline, but incorporating new technology into your network can compromise its performance. Often warehouses are having to attempt a balancing act between supporting these additional devices and applications, and minimising black-out spots, drop-offs and shrinking coverage.

As warehouse wireless experts, we know how to achieve 100% coverage in these unique and challenging environments where machines, racking, picking devices and even the building itself can compromise your connectivity. This blog discusses some tips you can use to boost your warehouse Wi-Fi coverage.

So how can you improve your warehouse wireless coverage?

Conduct a wireless network site survey

Start by conducting a Wi-Fi site survey to identify areas with weak signal coverage, interference sources, and dead zones. This survey helps determine the optimal placement of access points (APs) for better coverage and signal strength throughout the warehouse.

Upgrade to modern Wi-Fi standards

Ensure that your wireless infrastructure is based on the latest standards, such as 802.11ac or 802.11ax (Wi-Fi 5 or Wi-Fi 6). These standards offer improved speed, capacity, and performance compared to older versions. Upgrading to newer access points and compatible client devices can significantly enhance Wi-Fi performance.

Determine AP quantity – don’t overdo it!

When installing APs, you have to think about the size of your warehouse as well as the number of people working in it. Five people in a small warehouse can use one access point without any problem, as there will be enough bandwidth to go around. In a large warehouse, you’ll have to increase the number of APs in order to enjoy stable enterprise Wi-Fi coverage.

Optimise AP placement, taking racking and electronics into consideration

Proper placement of access points is crucial for effective coverage. Consider the warehouse layout, building materials, and the specific needs of each area when determining the ideal placement of access points. Mirrors, walls, machines and metal racks can prevent network signals from reaching some parts for your warehouse. Position them strategically to minimise interference from physical obstacles and metal structures that are common in warehouse environments to improve signal flow.

Manage channel interference

Warehouse environments often have various sources of interference, including machinery, equipment, and neighbouring networks. To mitigate interference, use Wi-Fi management tools to monitor and analyse channel usage. By selecting channels with less interference and adjusting channel widths, you can improve overall WLAN performance. If your router shares a channel with multiple Wi-Fi devices, you may experience signal issues. Use a less crowded channel to extend your wireless network signal range.

Optimise network configuration

Fine-tuning network configurations can enhance performance. Adjust settings such as channel bandwidth, transmit power, data rates, and Quality of Service (QoS) parameters to optimize performance for the specific requirements of the warehouse environment. Consult the documentation provided by your wireless equipment manufacturer for recommended settings.

Implement VLANs and network segmentation

Implementing VLANs (Virtual Local Area Networks) and network segmentation can help prioritise and manage network traffic effectively. Separate critical operations, such as inventory management or order processing, from general Wi-Fi usage to ensure that essential tasks receive the necessary bandwidth and network resources.

Update firmware and software

Regularly update the firmware and software of your wireless network equipment to ensure you have the latest features, bug fixes, and security enhancements. Keeping your devices up to date can help optimise performance and address any known issues.

Monitor and analyse performance

Utilise network monitoring and analysis tools to continuously monitor warehouse wireless performance, identify bottlenecks, and troubleshoot issues proactively. These tools can provide insights into network traffic, signal strength, device connectivity, and potential performance bottlenecks, allowing you to make informed decisions for further optimisation. These are becoming increasingly automated through the use of APIs and cloud software, making productivity optimisation an effortless process.

Consider Professional Assistance

If optimising warehouse wireless performance becomes challenging, consider consulting with a professional network engineer or Wi-Fi specialist. They can perform a detailed analysis of your specific environment, recommend customised solutions, and assist in implementing best practices to maximise wireless performance to boost warehouse efficiency.

In our current digital age, it is essential to be connected to WiFi. The internet facilitates a huge part of our working life, and is of the utmost importance for business performance and productivity. Nowhere is this more true than within warehouses; a wireless connection to the internet is vital at every stage from the receiving docks, to the orders of the pickers, all the way to the outbound department, and has eliminated the need for long and time consuming paper trails.

However, this means that the strength and speed of your warehouse WiFi is now directly related to your overall warehouse productivity. If your wireless connection is great, then there are no problems, however, if your warehouse WiFi signal is poor, then there is the potential for your efficiency to fall dramatically.

As such, our experts have suggested a few ways to improve your warehouse WiFi signal, thereby directly improving your efficiency, helping your business to grow.

1. Update your firmware

All WiFi-based devices run off internal firmware, which plays a large part in how the WiFi signal is translated and used within the physical device. Old and out of date firmware may affect the speed at which WiFi is picked up and used, and therefore by updating your devices’ firmware you are likely to increase the speed of your wireless internet connection.

2. Antenna type and its direction

Most warehouse WiFi antennas are either directional or omni-directional. If you have a directional antenna, then it is vital to ensure that it’s pointed in the correct direction – that’s in the direction of where most of the warehouse WiFi usage takes place. If you have an omni-directional antenna then make sure it’s placed as centrally as possible within your warehouse, so it maximises the speed and connection of the warehouse WiFi signal to your devices.

3. Metal cages

Warehouse safety is always key, and often protective metal cages are present throughout the building. However, these cages may have an affect on your warehouse WiFi signal, especially if the antenna is located directly within these cages. The metal used is likely to impact the RF communication of your WiFi, meaning that in order to prevent this from happening, you should always place your warehouse WiFi antennas outside of any metal cages.

To learn more about warehouse WiFi for your business, contact the team at Redway Networks today.